Standish Precision’s Independent Cam-Operated Plunger Press (ICOP) is a multi-station, deep draw transfer press that makes lower cost tooling a reality. Because the machine itself is a universal die set, tooling is confined to simple punches, die inserts, stripper sleeves and transfer fingers. The parts progress automatically from one station to another until the finished piece is formed and ejected.

What is I.C.O.P.?

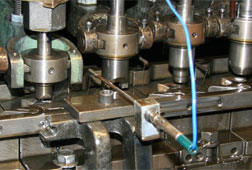

I.C.O.P. (Independent Cam-Operated Plunger Press) is a multiple-station, deep-draw transfer press. Each of 10 plungers is driven by its own cam, independent of every other plunger. The motion of each individually adjustable station can be synchronized with the machine’s fixed-time transfer mechanism. In effect, each station operates as an individual press – 10 presses in all. The part being advanced through the press is always supported by a punch or a pair of transfer fingers. The result is tooling simplicity, machine versatility, and high-speed operation with close tolerance control.

Continuous Operation

The sample parts shown were made in one continuous operation. With conventional production techniques, many of these parts would be two, three, four or even five-piece assemblies requiring stampings, drawn parts, tubing, and screw machine parts. All of our parts are made better, faster, and more economically by forming them as a single piece in our automated I.C.O.P. press.